Jyoti x Retraced: Transparency in global value chains – How can we make it happen?

What does transparency mean to us and how do we implement it?

Transparency has always been one of the most important issues for Jyoti. We want to know where our clothes have been, who has held them in their hands and under which conditions they were created.

This is why we work very closely and personally with the people involved in the production of our products. We have been cooperating with the Indian NGO Jyothi Seva Kendra in Chittapur for 8 years now, and some of the women in the sewing workshop have been there from the start. We are regularly on site to not only work together with the women on new designs, but also – and here we go one step further in our efforts to achieve transparency – to find, get to know and consciously select the people who are hidden in the furthest steps of the value chain, and who, for example, weave our fabrics or spin the yarn. Through many trips and lots of research, we have now built up a large network of fabric producers in India. This includes family businesses, weavers’ cooperatives, and even some impressive social enterprises that place a particular value on the sustainability of their products, the promotion of their craftsmanship, and the empowerment of previously disadvantaged population groups.

For us, however, transparency does not only mean gaining more knowledge for ourselves, and thus being able to work in a socially and ecologically sustainable manner, but also sharing these insights with you. We therefor strive to describe, as precisely as possible for each of our products, where our products come from explain, and have explained all the steps of our value chain on our homepage. On the one hand, it’s about how our clothing is made – from the cotton plant to the yarn, to the woven fabric and finally the finished product. On the other hand, we aim to bring the talented people behind the products to the forefront – the weavers and the nearly 20 women who run the two sewing workshops in Chittapur and Londa. Furthermore, we aim to provide you with a lots of useful information about materials, product life cycles, the design process, etc. via our blog and social media. But why is transparency so important to us?

And why is that important?

On the one hand, we want to raise awareness about where our clothes actually come from, how much work goes into making them and to whom do we owe it to. This creates an appreciation for our clothes as we automatically treat things that we value better. A better handling of our clothes – i.e. the care applied when wearing, washing and storing them, as well as the re-use care when we no longer wear them – results in products that live longer and do not end up in the trash as quickly – something that happens far too often in clothing production. (In our article series Circular Wardrobe, , as well as the blog article: Fashion without garbage we discuss more closely the topic of fashion, garbage and responsible use.)

Increased awareness of textile value chains also leads to a critical examination of the conventional textile industry and its shortcomings on an ecological and social level. We want to encourage people to inquire, do research and, ultimately, to make their own responsible consumption decisions. At the same time, we strive to set a good example for others and hope to call for more transparency for everyone in the long term, so that companies can no longer hide poor production conditions so easily and instead be held responsible for them.

Stumbling blocks on the way to transparent supply chains

Consistently working transparently is not easy. A textile value chain consists of many, individual steps that are carried out by many different people. Those who are at the very front of the value chain and harvest the cotton, for example, will in most cases never see the finished product and instead simply pass on their product (the cotton) to the next person in the chain. These are often wholesale markets that make it impossible to trace the raw materials, or middlemen who place orders without disclosing where the products are going.

There is a reason for this fine subdivision of value chains, which is closely related to the specialisation on individual work steps. Of course, specialisation is more economical than producing everything from a single source, and even in traditional handicrafts, it is common for certain groups to concentrate on one craft and pass the products on to the next steps for further processing. One example is the art of block printing, a technique in which large fabrics are printed extensively with wooden stamps; a practice which many families in the area around Jaipur, a city in the Indian state of Rajasthan, follow. The block itself is a wooden block with filigree patterns, carved by particularly dexterous artists in the Muslim quarter, known for it’s narrow streets, at the centre of Jaipur. The white, simple cotton fabrics are made by weavers in the area, and as a final step, everything ends up with the “Chippa”, who dye the fabrics and print them with their stamps. A similar division of labour can be observed in Pochampally, a village near Hyderabad, where ikat fabrics are traditionally produced (see our Blogentry about Ikat.

This characteristic of production chains makes it difficult – whether consciously sustainable or conventional production – to maintain personal contact with everyone involved. There are simply too many. If personal contacts are no longer sufficient or our capacities are exceeded, we need some support for consistent transparency and that’s why we started working with Retraced about 6 months ago.

Our cooperation with retraced

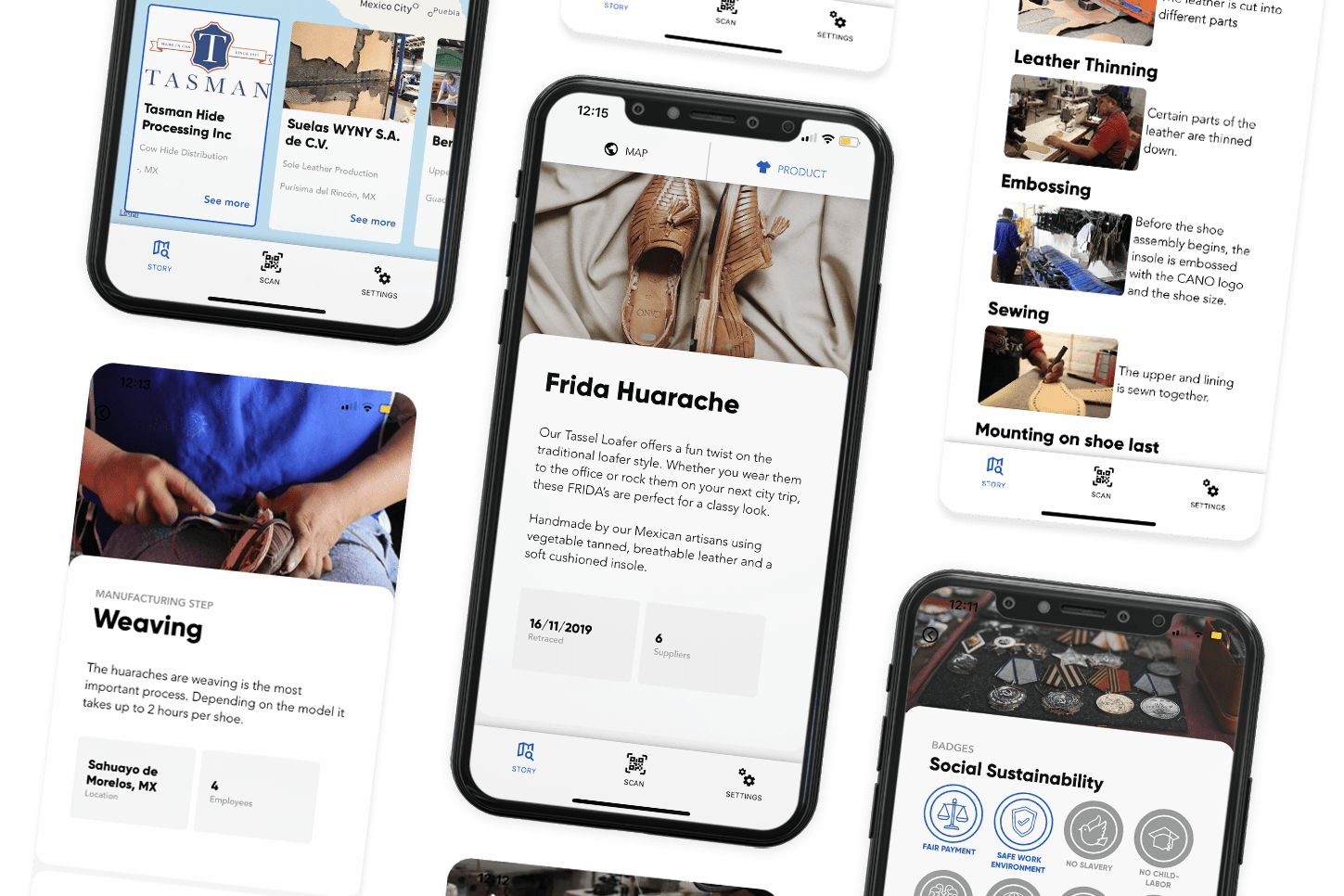

Retraced is a platform that supports fashion companies by bringing more transparency into their value chain. With the help of its solution, fashion companies can more easily track their value chain, collect data on their production standards and present these to their end-consumers. Retraced helps to simplify data collection and tracking for the brands, and to evaluate and verify the data received. If a customer is interested in one of the tracked products, he/she can view the data both in the store and when shopping online, and can easily get an idea of the product, its history, and make sure that the data shown is correct.

How exactly does this work? The principle is very simple. Everyone who is responsible for a step in our value chain becomes their own retraced user and confirms in an app when he or she has done the respective production step. This could be the spinning of a roll of yarn, the weaving of 100m of fabric, or the sewing of the individual products and then the shipping of them to Germany. The app, for example, can recognize where the order was processed, or can calculate product and fabric quantities and compare this with our production data.

What has already happened and what’s next?

In the past few months, we have already taken the first steps in our cooperation. In November, Caro was on site visiting the sewing workshops and many of our fabric dealers and retraced all the people involved in the manufacture of our products and presented the data collection app that we want to work with going forward. In addition to securing our value chains, retraced enables us to clearly illustrate the journey of each individual product and bring it closer to you. From now on you will find a QR code in each of our garments, which you can easily scan to see all the details of its history at a glance.

The nice thing is that Retraced is always working in the background, linking everyone in the value chain. So it is no longer just up to us, but to the efforts of many, many individuals who pool their information and complement each other. For example, Retraced independently contacts our fabric producers and asks them to provide further information about the suppliers, the raw materials, etc. Bit by bit, this creates a larger and more and more transparent picture of global value chains.

We hope, of course, that we will not remain alone in this endeavor, and that more and more manufacturing companies will decide to pursue and present more transparency. The more they voluntarily decide to do so and thereby set the new standards, the greater the pressure is on those companies who remain, and thus the greater the likelihood that production chains will become fairer and more sustainable.

We are very excited that the FORBES Magazine wrote an article about our cooperation with retraced which you can find here.